Carbon Steel Angle

Classification :

Product Description

Angle steel, commonly known as angle iron, is a long strip of steel with two sides perpendicular to each other. Angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks, cable trench supports, power piping, bus support installation, and warehouse shelves. Angle steel is carbon structural steel for construction, is a simple section of steel, mainly used for metal components and the framework of the plant. In use, it is required to have good weldability, plastic deformation performance and mechanical strength.

Product Parameters

Material | A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

Scope of production | H100*100-H400*400H150*75 -H900*300 |

Thickness | 1-30mm |

Width | 15-400mm |

Length | 6m, 9m, 12mor according to customer requirements |

Technology | Hot rolled, welded |

Standard | ASTM,AISI,JIS,GB, DIN,EN |

Surface | Galvanized, painted;or according to your requirements |

supply capacity | 2000tons/Day |

Business Type | Manufacturer |

Certificate | ISO, SGS,BV |

Application | Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

loading port | Any port in China |

Packaging | Standard export packing or as your request |

Payment Method | Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

|

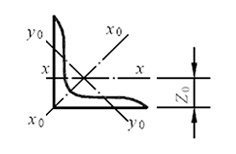

model

|

|

Single Angle Steel |

|

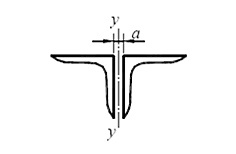

Double Angle Steel |

|||||||||||||

| Rounded Corners | Centroid Moment | Cross-sectional area | quality | Moment of inertia | Section modulus | Radius of gyration | iy, when a is the following value | ||||||||||

|

R |

Z0 |

A |

Ix |

Wxmax |

Wxmin |

ix |

ix0 |

iy0 |

6mm |

8mm |

10mm |

12mm |

14mm |

||||

|

(mm) |

(cm2) |

(kg/m) |

(cm4) |

(cm3) |

(cm) |

(cm) |

|||||||||||

|

L90×

|

6 |

10 |

24.4 |

10.64 |

8.35 |

82.77 |

33.99 |

12.61 |

2.79 |

3.51 |

1.8 |

3.91 |

3.98 |

4.05 |

4.12 |

4.2 |

|

|

7 |

24.8 |

12.3 |

9.66 |

94.83 |

38.28 |

14.54 |

2.78 |

3.5 |

1.78 |

3.93 |

4 |

4.07 |

4.14 |

4.22 |

|||

|

8 |

25.2 |

13.94 |

10.95 |

106.5 |

42.3 |

16.42 |

2.76 |

3.48 |

1.78 |

3.95 |

4.02 |

4.09 |

4.17 |

4.24 |

|||

|

10 |

25.9 |

17.17 |

13.48 |

128.6 |

49.57 |

20.07 |

2.74 |

3.45 |

1.76 |

3.98 |

4.06 |

4.13 |

4.21 |

4.28 |

|||

|

12 |

26.7 |

20.31 |

15.94 |

149.2 |

55.93 |

23.57 |

2.71 |

3.41 |

1.75 |

4.02 |

4.09 |

4.17 |

4.25 |

4.32 |

|||

|

L100× |

6 |

12 |

26.7 |

11.93 |

9.37 |

115 |

43.04 |

15.68 |

3.1 |

3.91 |

2 |

4.3 |

4.37 |

4.44 |

4.51 |

4.58 |

|

|

7 |

27.1 |

13.8 |

10.83 |

131 |

48.57 |

18.1 |

3.09 |

3.89 |

1.99 |

4.32 |

4.39 |

4.46 |

4.53 |

4.61 |

|||

|

8 |

27.6 |

15.64 |

12.28 |

148.2 |

53.78 |

20.47 |

3.08 |

3.88 |

1.98 |

4.34 |

4.41 |

4.48 |

4.55 |

4.63 |

|||

|

10 |

28.4 |

19.26 |

15.12 |

179.5 |

63.29 |

25.06 |

3.05 |

3.84 |

1.96 |

4.38 |

4.45 |

4.52 |

4.6 |

4.67 |

|||

|

12 |

29.1 |

22.8 |

17.9 |

208.9 |

71.72 |

29.47 |

3.03 |

3.81 |

1.95 |

4.41 |

4.49 |

4.56 |

4.64 |

4.71 |

|||

|

14 |

29.9 |

26.26 |

20.61 |

236.5 |

79.19 |

33.73 |

3 |

3.77 |

1.94 |

4.45 |

4.53 |

4.6 |

4.68 |

4.75 |

|||

|

16 |

30.6 |

29.63 |

23.26 |

262.5 |

85.81 |

37.82 |

2.98 |

3.74 |

1.93 |

4.49 |

4.56 |

4.64 |

4.72 |

4.8 |

|||

|

L110× |

7 |

12 |

29.6 |

15.2 |

11.93 |

177.2 |

59.78 |

22.05 |

3.41 |

4.3 |

2.2 |

4.72 |

4.79 |

4.86 |

4.94 |

5.01 |

|

|

8 |

30.1 |

17.24 |

13.53 |

199.5 |

66.36 |

24.95 |

3.4 |

4.28 |

2.19 |

4.74 |

4.81 |

4.88 |

4.96 |

5.03 |

|||

|

10 |

30.9 |

21.26 |

16.69 |

242.2 |

78.48 |

30.6 |

3.38 |

4.25 |

2.17 |

4.78 |

4.85 |

4.92 |

5 |

5.07 |

|||

|

12 |

31.6 |

25.2 |

19.78 |

282.6 |

89.34 |

36.05 |

3.35 |

4.22 |

2.15 |

4.82 |

4.89 |

4.96 |

5.04 |

5.11 |

|||

|

14 |

32.4 |

29.06 |

22.81 |

320.7 |

99.07 |

41.31 |

3.32 |

4.18 |

2.14 |

4.85 |

4.93 |

5 |

5.08 |

5.15 |

|||

|

L125× |

8 |

14 |

33.7 |

19.75 |

15.5 |

297 |

88.2 |

32.52 |

3.88 |

4.88 |

2.5 |

5.34 |

5.41 |

5.48 |

5.55 |

5.62 |

|

|

10 |

34.5 |

24.37 |

19.13 |

361.7 |

104.8 |

39.97 |

3.85 |

4.85 |

2.48 |

5.38 |

5.45 |

5.52 |

5.59 |

5.66 |

|||

|

12 |

35.3 |

28.91 |

22.7 |

423.2 |

119.9 |

47.17 |

3.83 |

4.82 |

2.46 |

5.41 |

5.48 |

5.56 |

5.63 |

5.7 |

|||

|

14 |

36.1 |

33.37 |

26.19 |

481.7 |

133.6 |

54.16 |

3.8 |

4.78 |

2.45 |

5.45 |

5.52 |

5.59 |

5.67 |

5.74 |

|||

|

L140×

|

10 |

14 |

38.2 |

27.37 |

21.49 |

514.7 |

134.6 |

50.58 |

4.34 |

5.46 |

2.78 |

5.98 |

6.05 |

6.12 |

6.2 |

6.27 |

|

|

12 |

39 |

32.51 |

25.52 |

603.7 |

154.6 |

59.8 |

4.31 |

5.43 |

2.77 |

6.02 |

6.09 |

6.16 |

6.23 |

6.31 |

|||

|

14 |

39.8 |

37.57 |

29.49 |

688.8 |

173 |

68.75 |

4.28 |

5.4 |

2.75 |

6.06 |

6.13 |

6.2 |

6.27 |

6.34 |

|||

|

16 |

40.6 |

42.54 |

33.39 |

770.2 |

189.9 |

77.46 |

4.26 |

5.36 |

2.74 |

6.09 |

6.16 |

6.23 |

6.31 |

6.38 |

|||

|

L160×

|

10 |

16 |

43.1 |

31.5 |

24.73 |

779.5 |

180.8 |

66.7 |

4.97 |

6.27 |

3.2 |

6.78 |

6.85 |

6.92 |

6.99 |

7.06 |

|

|

12 |

43.9 |

37.44 |

29.39 |

916.6 |

208.6 |

78.98 |

4.95 |

6.24 |

3.18 |

6.82 |

6.89 |

6.96 |

7.03 |

7.1 |

|||

|

14 |

44.7 |

43.3 |

33.99 |

1048 |

234.4 |

90.95 |

4.92 |

6.2 |

3.16 |

6.86 |

6.93 |

7 |

7.07 |

7.14 |

|||

|

16 |

45.5 |

49.07 |

38.52 |

1175 |

258.3 |

102.6 |

4.89 |

6.17 |

3.14 |

6.89 |

6.96 |

7.03 |

7.1 |

7.18 |

|||

|

|

12 |

16 |

48.9 |

42.24 |

33.16 |

1321 |

270 |

100.8 |

5.59 |

7.05 |

3.58 |

7.63 |

7.7 |

7.77 |

7.84 |

7.91 |

|

|

14 |

49.7 |

48.9 |

38.38 |

1514 |

304.6 |

116.3 |

5.57 |

7.02 |

3.57 |

7.67 |

7.74 |

7.81 |

7.88 |

7.95 |

|||

|

16 |

50.5 |

55.47 |

43.54 |

1701 |

336.9 |

131.4 |

5.54 |

6.98 |

3.55 |

7.7 |

7.77 |

7.84 |

7.91 |

7.98 |

|||

|

18 |

51.3 |

61.95 |

48.63 |

1881 |

367.1 |

146.1 |

5.51 |

6.94 |

3.53 |

7.73 |

7.8 |

7.87 |

7.95 |

8.02 |

|||

|

L200× |

14 |

18 |

54.6 |

54.64 |

42.89 |

2104 |

385.1 |

144.7 |

6.2 |

7.82 |

3.98 |

8.47 |

8.54 |

8.61 |

8.67 |

8.75 |

|

|

16 |

55.4 |

62.01 |

48.68 |

2366 |

427 |

163.7 |

6.18 |

7.79 |

3.96 |

8.5 |

8.57 |

8.64 |

8.71 |

8.78 |

|||

|

18 |

56.2 |

69.3 |

54.4 |

2621 |

466.5 |

182.2 |

6.15 |

7.75 |

3.94 |

8.53 |

8.6 |

8.67 |

8.75 |

8.82 |

|||

|

20 |

56.9 |

76.5 |

60.06 |

2867 |

503.6 |

200.4 |

6.12 |

7.72 |

3.93 |

8.57 |

8.64 |

8.71 |

8.78 |

8.85 |

|||

|

24 |

58.4 |

90.66 |

71.17 |

3338 |

571.5 |

235.8 |

6.07 |

7.64 |

3.9 |

8.63 |

8.71 |

8.78 |

8.85 |

8.92 |

|||

Product Details

The company has rich experience and resources in overseas trade, and its products are exported to Europe, America, Asia and other countries and regions. The annual export volume exceeds US$50 million, accounting for more than 50% of the company's total sales.

Application Field

Customer Visit

COOPERATIVE PARTNER

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

FAQ

Q:What product information do I need to provide?

A:You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

Q:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.

Q: Do you provide samples ? is it free or extra ?

A: The sample could can provide for customer with free,but the courier freight will be covered by customer account.

Q:How to pack the products?

A:The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation.

Q: Do you accept the third party inspection?

A: Yes absolutely we accept.

Q:How about MOQ?

A:The minimum order quantity is 3 Ton, which can be customized according to customer requirements.

RELATED PRODUCTS

GET A FREE QUOTE